HRVYST Quality Engineer: Ensuring Product Excellence

Introduction

The role of a HRVYST Quality Engineer is crucial to maintaining the high standards that set HRVYST apart in the agriculture and tech industry. A HRVYST Quality Engineer doesn’t just check for product defects; they ensure each step in production aligns with the company’s commitment to quality. By carefully monitoring processes and implementing quality controls, these engineers play a significant role in creating reliable, high-performance products. This role involves a deep understanding of both quality engineering principles and the unique demands of agricultural technology. HRVYST’s quality engineers are proactive, aiming to catch and prevent potential issues early. This article delves into the responsibilities, skills, methodologies, and career growth opportunities for a HRVYST Quality Engineer, showcasing why this position is critical in delivering products that meet the company’s—and the customer’s—high expectations.

Key Responsibilities of a HRVYST Quality Engineer

A HRVYST Quality Engineer holds various responsibilities that are essential for producing top-quality products. They conduct quality checks throughout the production process, making sure every product meets HRVYST’s rigorous standards. This engineer oversees quality control processes, documents findings, and maintains a close eye on any changes needed to improve quality. They’re responsible for implementing quality improvement strategies, such as adjusting production techniques, optimizing procedures, and, importantly, ensuring team alignment on quality goals. Furthermore, a HRVYST Quality Engineer also collaborates with other teams to improve processes, minimize waste, and, ultimately, optimize efficiency. Their work directly influences customer satisfaction, product reliability, and brand trust. By embedding quality at every step, HRVYST ensures that each product meets and often exceeds customer expectations, showcasing the value of dedicated quality engineering.

Skills and Qualifications Required for HRVYST Quality Engineers

The position of HRVYST Quality Engineer requires a specific set of skills and qualifications. Technical expertise in quality assurance and control is a fundamental requirement, along with a strong grasp of industry standards and regulations. Knowledge of agricultural technology is especially valuable in this role, as quality engineers must work with products and processes unique to this field. Analytical skills are key, enabling engineers to assess data and make decisions that enhance product quality. Additionally, effective communication skills are vital for collaborating with diverse teams, ensuring that everyone understands and adheres to quality standards. HRVYST values problem solvers who can think critically and adapt to changes in technology or industry practices. The ability to innovate and find new solutions to common issues is what makes a HRVYST Quality Engineer an essential asset to the company’s ongoing success and growth.

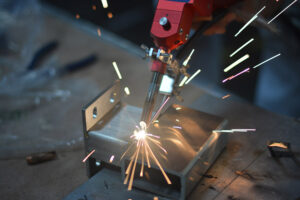

Quality Engineering Processes Used by HRVYST

HRVYST Quality Engineers use a range of processes to ensure product excellence. They often rely on methodologies like Six Sigma, which aims to reduce variability, and Lean principles, which focus on cutting waste within production. These methodologies help HRVYST maintain efficiency without compromising quality. Engineers at HRVYST utilize tools like statistical process control (SPC) software and failure mode and effects analysis (FMEA) to track quality metrics, identify trends, and address potential issues before they impact the final product. By embedding quality checks at each stage of production rather than relying on end-stage inspections, HRVYST ensures consistency and reliability. Through these practices, HRVYST is able to meet customer expectations and maintain its position as a leader in quality agricultural products, showcasing the importance of dedicated engineering processes.

Challenges and Solutions in Quality Engineering at HRVYST

Like any dynamic field, quality engineering at HRVYST comes with unique challenges. For a HRVYST Quality Engineer, staying updated with advancements in technology and agricultural practices is crucial. As new products and processes are developed, quality engineers must adapt their methods to maintain high standards. Scaling quality procedures for larger production volumes can be complex, but HRVYST trains its engineers to apply flexible approaches. Identifying defects before they affect the final product is also a challenge; HRVYST addresses this by integrating quality checkpoints throughout production, which helps catch issues early. These proactive measures, combined with ongoing training and adaptation, help HRVYST Quality Engineers maintain smooth operations and uphold product excellence, proving that HRVYST values continuous improvement and dedication to quality.

Career Path and Opportunities for HRVYST Quality Engineers

Becoming a HRVYST Quality Engineer offers a promising career path with opportunities for growth and advancement. Entry-level engineers gain hands-on experience in quality control, learning the detailed processes involved in maintaining product standards. With experience, they can move into senior roles, such as lead quality engineer or quality manager, where they have greater influence over quality policies and initiatives. HRVYST encourages its engineers to develop their skills, offering access to professional development programs and industry training. A career in quality engineering at HRVYST allows professionals to work with advanced technologies in agriculture, making an impact within a company that prioritizes quality. For those interested in both technology and agriculture, HRVYST provides a challenging and rewarding career where engineering expertise is valued and supported.

Impact of HRVYST Quality Engineers on Product Success

The work of a HRVYST Quality Engineer is integral to the success of the company’s products. By embedding quality checks throughout production, quality engineers help ensure that each product lives up to HRVYST’s standards. This directly affects customer satisfaction and brand trust, as products that consistently meet or exceed expectations strengthen HRVYST’s reputation. Quality engineers at HRVYST don’t just ensure standards are met—they actively enhance the product development process, reducing the chance of costly recalls and complaints. In a competitive market, this commitment to reliability and consistency provides HRVYST with an edge. By prioritizing quality at each stage, these engineers play a key role in fostering customer loyalty and reinforcing HRVYST as a leader in agricultural technology.

( FAQs )

- What does an HRVYST Quality Engineer do?

They ensure products meet high quality standards through control processes and improvements. - What skills are needed for this role?

Key skills include quality control expertise, analytical thinking, and effective communication. - What challenges do they face?

Common challenges include adapting to new tech and scaling quality processes. - How can a quality engineer grow at HRVYST?

They can advance from entry-level to senior roles, with opportunities for skill development.

Final Thoughts

The role of a HRVYST Quality Engineer is both challenging and fulfilling, offering a unique combination of technical expertise, problem-solving, and commitment to excellence. Quality engineers at HRVYST are crucial to maintaining high standards, creating processes that lead to reliable, high-quality products. By fostering a culture of continuous improvement and providing growth opportunities, HRVYST offers an environment where quality engineers can thrive and make an impact. For professionals passionate about quality in the tech-agriculture space, HRVYST represents a company where engineering expertise is appreciated and rewarded. The role of a quality engineer here goes beyond checking for flaws—it’s about embedding excellence at every step, contributing to products that align with HRVYST’s vision and commitment to innovation and quality.

Post Comment